The Definitive Guide for Premier Aluminum Llc

The Definitive Guide for Premier Aluminum Llc

Blog Article

What Does Premier Aluminum Llc Mean?

Table of ContentsIndicators on Premier Aluminum Llc You Should KnowExcitement About Premier Aluminum LlcPremier Aluminum Llc Can Be Fun For AnyoneThe 8-Minute Rule for Premier Aluminum Llc

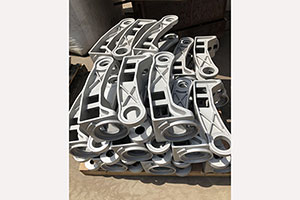

(https://www.brownbook.net/business/53359936/premier-aluminum-llc/)Traditionally, a buyer's primary duty was to find qualified and responsive suppliers. In many cases, purchasers presumed that any supplier happy to contractually fulfill the purchase demand was certified. Utilizing reduced price and unqualified vendors can trigger quality concerns, and squandered time and cash in the lengthy run. To aid you via the procedure, here are some things to consider when picking the best steel spreading vendor.

A firm that only uses the investment casting procedure will try to market you on why that process is best for your application (Aluminum Castings). What if utilizing the sand casting procedure is best for you and your demands? Instead, look for a provider that supplies a series of casting processes so the best option for YOU is chosen

If working with a solitary source for every one of your casting requires is necessary to you, the vendor requires to be varied in its capabilities. When integrated with other incorporated capabilities, this can help streamline and press the supply base. When choosing the right spreading distributor, mindful consideration needs to be given to quality, solution, and rate.

All about Premier Aluminum Llc

Buyers progressively pick spreading providers that have machining capacities. This can avoid problem if flaws are discovered during machining. If a third event is machining, it may cause "finger-pointing" about that is at mistake. Is it a spreading concern or a machining problem? If the casting vendor uncovers an issue throughout machining, the trouble is dealt with much faster without any conflict over whose fault it is.

Issue or no, integrated machining simplifies the supply chain and lowers managing time and delivery expense before the product makes it to the client. What do you need from your spreading vendor? Are you searching for someone to just provide a steel element to your doorstep or do you require much more? As an example, if you do not have in-house metallurgy know-how, validate that the distributor can provide advice in picking the proper alloy based upon your specific application - Aluminum Casting.

Some factories are limited or specialized. Make sure the supplier can satisfy all your material or alloy needs to get rid of the requirement for numerous vendors.

Some Of Premier Aluminum Llc

Research study the supplier's site. Speak with a sales associate or company associate. Ask a great deal of questions. Visit their center. Get an understanding of what they can do for you and if you can see yourself constructing a strong, common partnership with them.

Light weight aluminum is likewise light-weight and has good deterioration resistance, making it suitable for applications where weight and toughness are very important variables. Furthermore, aluminum spreading is an economical approach of production, as it needs much less power and resources than various other approaches. Iron casting, on the other hand, includes pouring molten iron right into a mold and mildew to develop a wanted form.

Indicators on Premier Aluminum Llc You Should Know

Iron casting is likewise able to hold up against heats, making it suitable for use in applications such as engine parts and commercial machinery. Iron spreading can be extra costly than light weight aluminum spreading due to the greater price of raw products and the energy needed to melt the iron. When making a decision between aluminum spreading and iron casting, it is essential to think about the certain needs of the application.

If toughness and longevity are more important, iron spreading might be the better alternative. Various other elements to consider consist of expense, manufacturing volume, and lead time. In conclusion, both light weight aluminum casting and iron casting have their very own special advantages and disadvantages. By carefully taking into consideration the certain requirements of the application, manufacturers can pick the ideal procedure for their product.ZheJiang Dongrun Casting Sector Co,. Ltd was developed in 1995, We have actually remained in the casting sector for greater than 25 years. Pass away spreading is the name provided to the

procedure of producing complex steel elements through use molds of the element, also referred to as dies. The procedure uses non-ferrous metals which do not include iron, such as aluminum, zinc and magnesium, as a result of the preferable buildings of the steels such as reduced weight, greater conductivity, non-magnetic conductivity and resistance to corrosion. Pass away casting production is fast, making high manufacturing levels of elements very easy.

It creates even more components than any type of various other process, with a high degree of precision and repeatability. To get more information regarding die spreading and die casting materials made use of while doing so, checked out on. There are 3 sub-processes that drop under the category Foundry of die casting: gravity pass away spreading (or permanent mold spreading), low-pressure die spreading and high-pressure die spreading. The pure metal, also called ingot, is contributed to the furnace and maintained the molten temperature of the steel, which is then transferredto the injection chamber and injected into the die. The pressure is after that kept as the steel strengthens. As soon as the metal solidifies, the cooling process begins. The thicker the wall of the part, the longer the cooling time due to the quantity of indoor steelthat also needs to cool. After the component is fully cooled, the die halves open and an ejection mechanism pushes the component out. Complying with the ejection, the die is closed for the next injection cycle. The flash is the extra material that is cast during the process. This should be trimmed off using a trim tool to

leave simply the main part. Deburring gets rid of the smaller sized items, called burrs, after the cutting process. Lastly, the element is polished, or burnished, to offer it a smooth coating. This confirmed to be an inaccurate examination, due to the fact that the tester might cut right into an item and miss an area with porosity. Today, leading suppliers make use of x-ray testing to see the entire inside of elements without cutting right into them. This enables them to much more accurately approve or turn down elements. To reach the ended up item, there are three key alloys made use of as die casting material to pick from: zinc, light weight aluminum and magnesium. Zinc is among one of the most used alloys for die spreading because of its lower price of basic materials. Report this page